Advantages

The turntable shaft accessory for bristle planting machines offers several notable advantages. Firstly, it ensures precise rotational performance. Designed to enable accurate and stable rotation of the turntable system in bristle planting machinery, it enhances the precision and efficiency of bristle placement, which is crucial for producing uniform and high-quality brushes. Secondly, it boasts excellent durability. Constructed from high-strength metal materials, it resists wear, deformation, and mechanical stress, ensuring a long service life even under continuous industrial use. Moreover, it features strong compatibility. Its design allows it to be integrated into various bristle planting machine models, meeting diverse rotational and bristle planting needs. Additionally, it enables easy integration and maintenance. The component can be seamlessly incorporated into existing turntable systems of bristle planting machines, and its robust structure simplifies routine upkeep, minimizing downtime.

Detailed Features

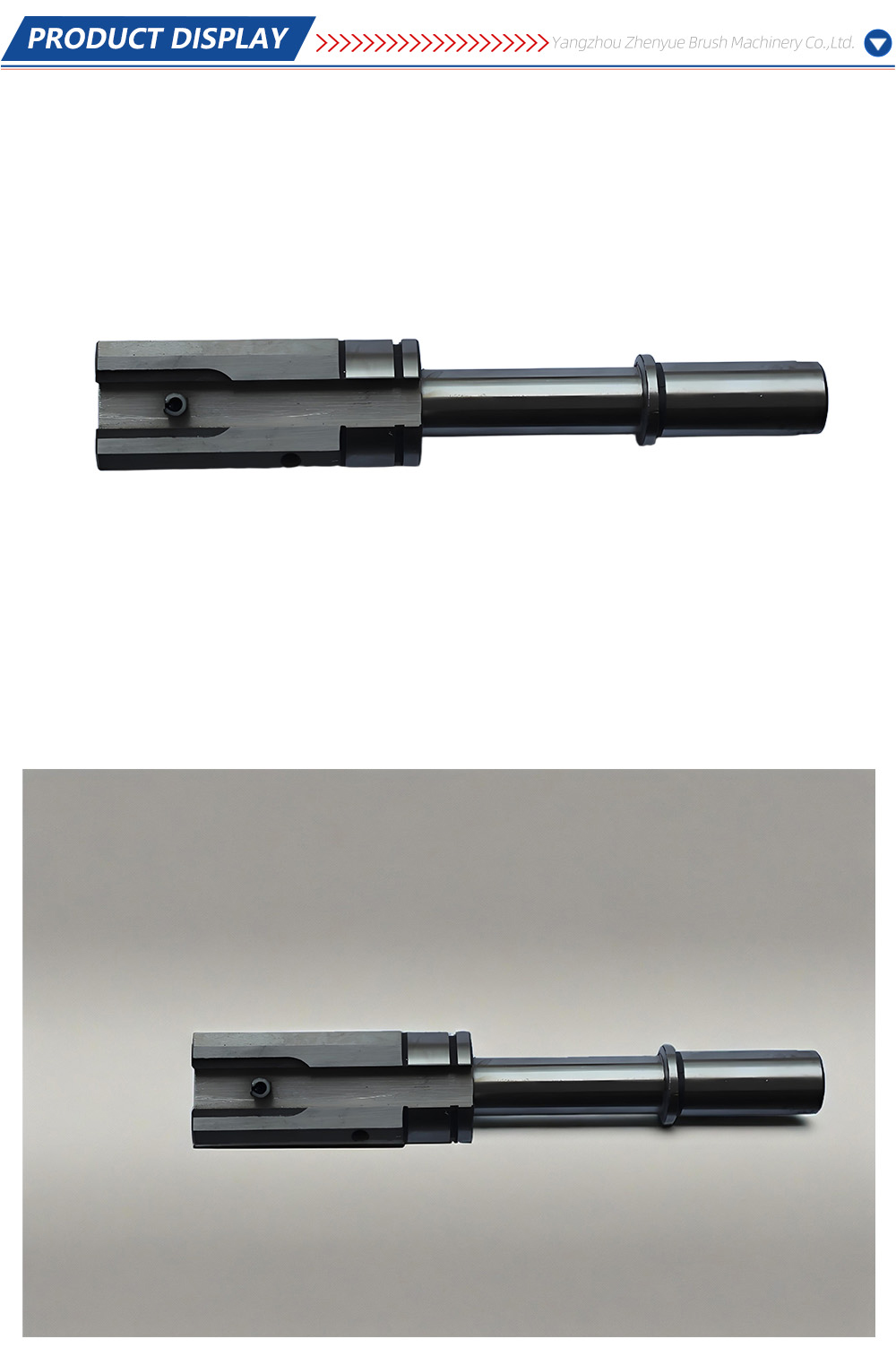

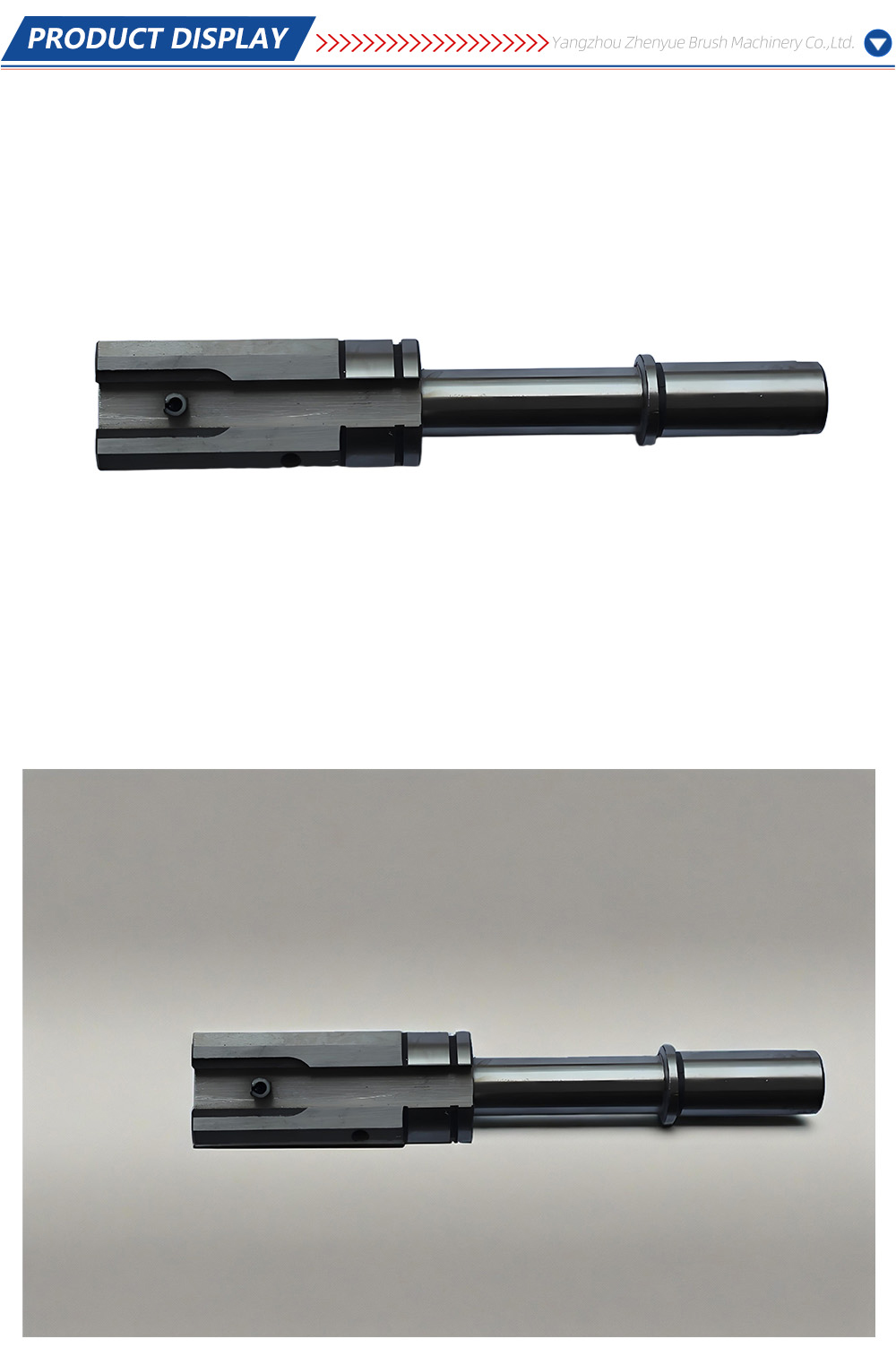

In terms of detailed features, the turntable shaft has a robust and precision-engineered structure. As visible in the image, it is a cylindrical metal component with segmented designs, including smooth shafts and structured connectors. It is made of high-quality, wear-resistant metal that guarantees structural integrity during intensive rotational operations. The precision machining process ensures tight dimensional tolerances, allowing for smooth coordination with bearings, gears, and other turntable components. Furthermore, the component includes secure mounting points and polished surfaces to ensure stable rotation and reduce friction. Rigorous quality control ensures it meets industry standards for strength and precision, making it a dependable part of turntable systems in bristle planting machinery.

Application Range

The application range of this turntable shaft accessory is concentrated in brush manufacturing industries, specifically for bristle planting machines. It is suitable for use in producing various brushes, including household cleaning brushes, industrial brushes, and personal care brushes, where it plays a key role in enabling the turntable’s rotation for precise bristle planting into plastic, wood, or metal bases. In brush production facilities that require automated and precise bristle planting, it ensures consistent rotational performance, enhancing production efficiency and product quality. It is also relevant for machinery maintenance and upgrade projects in the brush manufacturing sector, where it replaces outdated or worn turntable shafts to restore optimal rotational and bristle planting performance. Whether in large-scale brush factories or specialized production workshops, this turntable shaft meets the demanding needs of bristle planting machinery with its reliable performance.